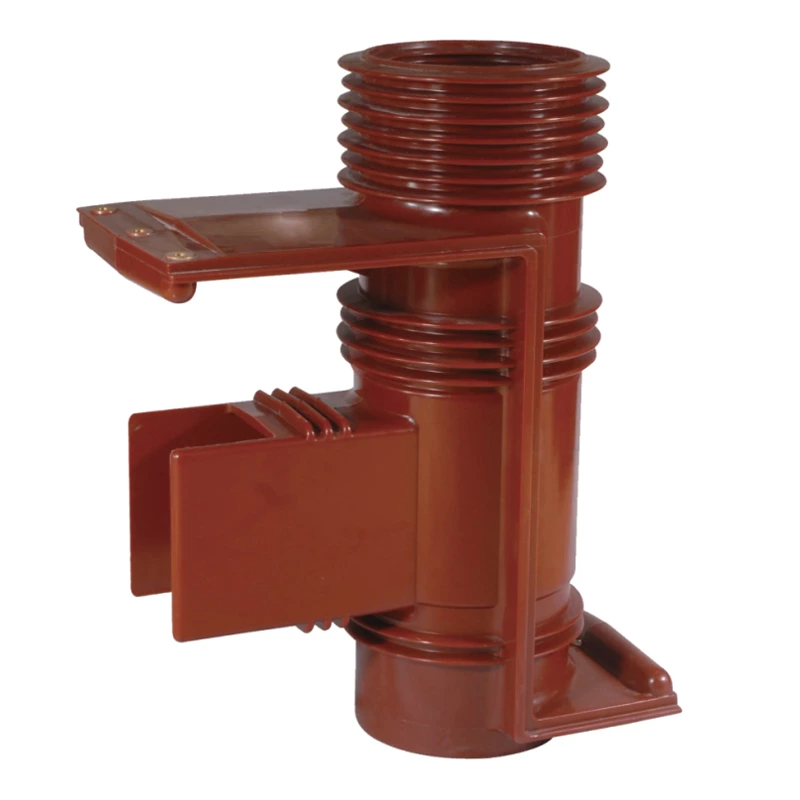

Double Shielding Contact Box Structure Principle

The structural principle of Insulation Contact Box mainly includes the following steps:

1. The contact box body can be made of solid insulating medium such as epoxy resin, and its glass transition temperature must be greater than 105℃. At the same time, in order to have sufficient insulation strength and mechanical strength, its material thickness must be greater than 10mm, and the thickness of the flange surface material must be greater than 30mm.

2. In order to better cover the two layers of double shielding layers (i.e., high-voltage shielding layer and grounding shielding layer) and ensure that there is a suitable electric field strength between the two shielding layers, the material thickness at the double shielding layer must be greater than 45mm.

3. The live conductors are selected according to the actual current size used, and are all set in the middle of the contact box cavity, which can better improve the shielding effect.

4. The turning placement of the wiring harness inside the contact box is realized by the vertical and internally connected setting of the horizontal tube body and the vertical tube body.

5. Through the double-layer shielding setting of the inner shielding layer and the outer shielding layer inside the tube wall, the electromagnetic shielding effect of the contact box at the corner connection position is effectively guaranteed, reducing the external influence.